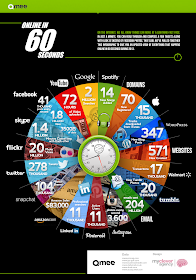

Qmee has published a pie chart showing what happens every single minute in the internet. In a minute 1.8 millions of "Likes" were clicked in Facebook, 278,000 tweets published, 204 million of emails sent...

Wednesday, July 31, 2013

Tuesday, July 30, 2013

Ingenious Designs Of Furniture Made From Recycled Cardboard

Chairigami is an innovative designer and manufacturer of cardboard

furniture. It was founded by Yale graduate Zach Rotholz. He first became familiar with cardboard furniture while working

during a summer in college for Adaptive Design, a New York City

nonprofit that custom-designs cardboard furniture for children with

disabilities.

Chairigami provides lightweight, flatpacking and recycable products to fill the need for temporary yet durable

furniture. The furniture is free of nasty resins and glues. Chairigami believes in producing recyclable

furniture from renewable resources. Each piece of furniture is hand crafted right in the store located at New Haven, Connecticut, U.S.A.

Chairigami is now making a wide variety

of products, ranging from sofas, desk chairs, standing desks,

coffee tables, shelving, and even an iPhone case. The chairs last about a

year and the tables can service you up to 4 years.

But, they are not selling cheap. A chair of size 18"W x 30"H x 40"D sells for US$80 and a sofa of size 44"W x 32"L x 28"H would sell for US$120.

Friday, July 26, 2013

New User-Friendly Software To Compare Climate Change Data Of World's Countries

The World Resources Institute has developed a web-based app called CAIT 2.0 which allows users to quickly comparing the total emissions, emission by gases and sectors, and to

look up figures in absolute terms, per capita and by year-on-year

change, of the world's 186 countries.

It is user-friendly and I have created a comparison chart of 2010 total carbon emission and emission per capita (excluding LUCF- land use change and forestry) of the 10 countries in South-East Asia. Clearly can be seen that Indonesia has the highest total carbon emission, this is because it has the highest population. When come to emission per capita Brunei ranks highest and Singapore seconds, my country Malaysia actually in the third place. Comparing to the GDP per capita, Singapore is highest, Brunei second and Malaysia third in South-East Asia. This should contribute to the high GHG per capita.

Thursday, July 25, 2013

World's Largest Solar Power Plant Opening in California

The largest solar

power plant in the world will open in California's Mojave Desert. Unlike conventional photovoltaic systems, this solar thermal facility

generates heat. 170,000 mirrors, stretching over 3,500 acres,

reflect direct sunlight toward 3 towers filled with water,

raising temperatures to more than 1,000 degrees Fahrenheit. The water

turns to steam, spinning turbines that generate electricity. The

electricity generated is enough

to power more than 140,000 homes during the peak hours of the day.

BrightSource Energy, the company overseeing construction, claims the

use of sunlight, instead of fossil fuels, will reduce CO2 emissions by

more than 400,000 tons per year. A highly efficient location, the desert

region receives reliable sunlight 330 to 350 days per year, according

to the Smithsonian.

Is this technology suitable for Malaysia? The answer mostly is No! This is because solar thermal technology requires "direct sunlight" to operate. Malaysia's weather is mostly cloudy. During cloudy day we will only get "diffused sunlight" and the "mirrors" will not be able to collect and reflect it toward the tower.

Source: http://www.renewableenergyworld.com/rea/blog/post/2013/07/the-worlds-largest-solar-power-plant-opening-in-california

Source: http://www.renewableenergyworld.com/rea/blog/post/2013/07/the-worlds-largest-solar-power-plant-opening-in-california

How Close Can A Wind Farm Be Built To A Home In Australia?

This graph highlights some of the absurdities about set back rules in the Victoria state of Australia. According to the rules, new wind farms must be set back at least 2 km from the nearest household. Ironically that coal-fired power plants can be sited within 1 km, and gas wells within 100 m.

Wednesday, July 24, 2013

Solar Module Expects 20% Cheaper Than Last Year

Solar market was going thru a bumpy road for the past few years. Many manufacturers had gone out of business due to negative margins caused by oversupply. After re-balancing of the market, and the Chinese, Japanese and US

markets drive strong growth, the remaining manufacturers are in positive

territory.

From traditional economic, one would expect price rebound after the market re-balanced and would never be seen the cheap modules again. This phenomenon would only happen if the module price fall was driven only by over-capacity,

but what is clear from most manufacturers is that the cost of

manufacture of solar modules will also continue to fall, and in some

cases quite dramatically.

REC Solar, one of the leading European solar companies produced graph showing solar

ability to undercut fossil fuels over the long term, because it shows

that the cost of manufacture of a solar module will fall around 20% over the year – despite the 60% to 80% falls achieved over the

previous 3 to 4 years. The same story is expected to be repeated

among many other manufacturers.

Tuesday, July 23, 2013

BOXED - A Wooden Briefcase Transforms Into Desk And Stools

Tyrone Stoddart, a designer from Scotland, has come out with an ingenious wooden briefcase, called BOXED, that can be transformed into a coffee table, a desk, two stools

and a lamp. All these parts then collapse back down to their most basic form, allowing them to be

returned to the briefcase.

The concept of BOXED is not only to be an useful furniture but also to educate customer about ash tree dieback disease and the use of materials in all their products. A small pouch of ash seeds is given to the consumer to go out and re-plant to ensure that there is an understanding of the problem of dieback in U.K. but also to replenish the materials that have been used in this project.

Saturday, July 20, 2013

Homemade 12V Sealed-Lead-Acid Battery Charger

We need 14.2V to proper charge a 12V sealed-lead-acid (SLA) batteries (like batteries in your car, computer UPS power supply, emergency light, etc). Too high a voltage will damage the batteries and too low the batteries will never get charged.

I use an old Acer laptop charger as the DC input source which gives about 19V. The homemade charger reduces the 19V to a stable 14.2V.

The charger composes LM317 voltage regulator, NPN transistor, capacitors and resistors. By setting the resistor

R3 (refer to circuit below) to 830 ohm I was able to get 14.2V of output. If you want to charge a 6V

SLA battery you can try to set R3 to ~ 120 ohm to output 7.1V.

REMINDERS:

(1) LM317 gets warm during charging so it needs to be mounted on heat sink.

(2) Never set the output more than 14.2V to charge 12V SLA battery.

(2) Never set the output more than 14.2V to charge 12V SLA battery.

(3) The charger is meant for SLA batteries only.

(4) Use cautiously and at your own risk.Thursday, July 18, 2013

UK Researchers Power Mobile Phone With Urine

Back in November 9 last year, I talked about 4 African teenagers developed an urine-powered generator. Now the "urine" idea continues to grow. Researchers from University of Bristol and Bristol Robotics Laboratory in south west England have developed a fuel cell that uses bacteria to break down urine to generate electricity.

"No one has harnessed power from urine to do this so it's an exciting discovery," said engineer Ioannis Ieropoulos. "The beauty of this fuel source is that we are not relying on the erratic nature of the wind or the sun; we are actually reusing waste to create energy."

The team created the microbial fuel cell by growing bacteria on carbon fiber anodes and place them inside ceramic cylinders. The bacteria broke down chemicals in urine passed through the cylinders, building up a small amount of electricity which stored in a capacitor. Currently, the fuel cell has the size of a car battery and able to power the mobile phone to send SMS, browse the web and carry on with a short phone call. Now, the team is working to make the cell even more compact and portable so that it can be carried around easily and used to charge any type of gadget.

Researchers from the

University of Bristol and Bristol Robotics Laboratory in south west

England said they had created a fuel cell that uses bacteria to break

down urine to generate electricity, in a study published in the Royal

Society of Chemistry journal Physical Chemistry Chemical Physics.

"No one has harnessed power from urine to do this so it's an exciting discovery," said engineer Ioannis Ieropoulos.

"The beauty of this fuel source is that we are not relying on the erratic nature of the wind or the sun; we are actually reusing waste to create energy.

"One product that we can be sure of an unending supply is our own urine," he added.

The team grew bacteria on carbon fibre anodes and placed them inside ceramic cylinders.

The bacteria broke down chemicals in urine passed through the cylinders, building up a small amount of electrical charge which was stored on a capacitor.

Ieropoulos hoped that the cell, which is currently the size of a car battery, could be developed for many applications.

"Our aim is to have something that can be carried around easily," he explained.

"So far the microbial fuel power stack (MFC) that we have developed generates enough power to enable SMS messaging, web browsing and to make a brief phone call.

"The concept has been tested and it works - it's now for us to develop and refine the process so that we can develop MFCs to fully charge a battery."

They hope the technology will eventually be used to power domestic devices.

Read more at: http://phys.org/news/2013-07-scientists-power-mobile-urine.html#jCp

"No one has harnessed power from urine to do this so it's an exciting discovery," said engineer Ioannis Ieropoulos.

"The beauty of this fuel source is that we are not relying on the erratic nature of the wind or the sun; we are actually reusing waste to create energy.

"One product that we can be sure of an unending supply is our own urine," he added.

The team grew bacteria on carbon fibre anodes and placed them inside ceramic cylinders.

The bacteria broke down chemicals in urine passed through the cylinders, building up a small amount of electrical charge which was stored on a capacitor.

Ieropoulos hoped that the cell, which is currently the size of a car battery, could be developed for many applications.

"Our aim is to have something that can be carried around easily," he explained.

"So far the microbial fuel power stack (MFC) that we have developed generates enough power to enable SMS messaging, web browsing and to make a brief phone call.

"The concept has been tested and it works - it's now for us to develop and refine the process so that we can develop MFCs to fully charge a battery."

They hope the technology will eventually be used to power domestic devices.

Read more at: http://phys.org/news/2013-07-scientists-power-mobile-urine.html#jCp

Researchers from the

University of Bristol and Bristol Robotics Laboratory in south west

England said they had created a fuel cell that uses bacteria to break

down urine to generate electricity, in a study published in the Royal

Society of Chemistry journal Physical Chemistry Chemical Physics.

"No one has harnessed power from urine to do this so it's an exciting discovery," said engineer Ioannis Ieropoulos.

"The beauty of this fuel source is that we are not relying on the erratic nature of the wind or the sun; we are actually reusing waste to create energy.

"One product that we can be sure of an unending supply is our own urine," he added.

The team grew bacteria on carbon fibre anodes and placed them inside ceramic cylinders.

The bacteria broke down chemicals in urine passed through the cylinders, building up a small amount of electrical charge which was stored on a capacitor.

Ieropoulos hoped that the cell, which is currently the size of a car battery, could be developed for many applications.

"Our aim is to have something that can be carried around easily," he explained.

"So far the microbial fuel power stack (MFC) that we have developed generates enough power to enable SMS messaging, web browsing and to make a brief phone call.

"The concept has been tested and it works - it's now for us to develop and refine the process so that we can develop MFCs to fully charge a battery."

They hope the technology will eventually be used to power domestic devices.

Read more at: http://phys.org/news/2013-07-scientists-power-mobile-urine.html#jCp

"No one has harnessed power from urine to do this so it's an exciting discovery," said engineer Ioannis Ieropoulos.

"The beauty of this fuel source is that we are not relying on the erratic nature of the wind or the sun; we are actually reusing waste to create energy.

"One product that we can be sure of an unending supply is our own urine," he added.

The team grew bacteria on carbon fibre anodes and placed them inside ceramic cylinders.

The bacteria broke down chemicals in urine passed through the cylinders, building up a small amount of electrical charge which was stored on a capacitor.

Ieropoulos hoped that the cell, which is currently the size of a car battery, could be developed for many applications.

"Our aim is to have something that can be carried around easily," he explained.

"So far the microbial fuel power stack (MFC) that we have developed generates enough power to enable SMS messaging, web browsing and to make a brief phone call.

"The concept has been tested and it works - it's now for us to develop and refine the process so that we can develop MFCs to fully charge a battery."

They hope the technology will eventually be used to power domestic devices.

Read more at: http://phys.org/news/2013-07-scientists-power-mobile-urine.html#jCp

Researchers from the

University of Bristol and Bristol Robotics Laboratory in south west

England said they had created a fuel cell that uses bacteria to break

down urine to generate electricity, in a study published in the Royal

Society of Chemistry journal Physical Chemistry Chemical Physics.

"No one has harnessed power from urine to do this so it's an exciting discovery," said engineer Ioannis Ieropoulos.

"The beauty of this fuel source is that we are not relying on the erratic nature of the wind or the sun; we are actually reusing waste to create energy.

"One product that we can be sure of an unending supply is our own urine," he added.

The team grew bacteria on carbon fibre anodes and placed them inside ceramic cylinders.

The bacteria broke down chemicals in urine passed through the cylinders, building up a small amount of electrical charge which was stored on a capacitor.

Ieropoulos hoped that the cell, which is currently the size of a car battery, could be developed for many applications.

"Our aim is to have something that can be carried around easily," he explained.

"So far the microbial fuel power stack (MFC) that we have developed generates enough power to enable SMS messaging, web browsing and to make a brief phone call.

"The concept has been tested and it works - it's now for us to develop and refine the process so that we can develop MFCs to fully charge a battery."

They hope the technology will eventually be used to power domestic devices.

Read more at: http://phys.org/news/2013-07-scientists-power-mobile-urine.html#jCp

"No one has harnessed power from urine to do this so it's an exciting discovery," said engineer Ioannis Ieropoulos.

"The beauty of this fuel source is that we are not relying on the erratic nature of the wind or the sun; we are actually reusing waste to create energy.

"One product that we can be sure of an unending supply is our own urine," he added.

The team grew bacteria on carbon fibre anodes and placed them inside ceramic cylinders.

The bacteria broke down chemicals in urine passed through the cylinders, building up a small amount of electrical charge which was stored on a capacitor.

Ieropoulos hoped that the cell, which is currently the size of a car battery, could be developed for many applications.

"Our aim is to have something that can be carried around easily," he explained.

"So far the microbial fuel power stack (MFC) that we have developed generates enough power to enable SMS messaging, web browsing and to make a brief phone call.

"The concept has been tested and it works - it's now for us to develop and refine the process so that we can develop MFCs to fully charge a battery."

They hope the technology will eventually be used to power domestic devices.

Read more at: http://phys.org/news/2013-07-scientists-power-mobile-urine.html#jCp

Wednesday, July 17, 2013

Most Efficient Semiconductor Device Triples Waste Heat Conversion

About half of the energy used today ends in form of waste heat. According to MicroPower Global if partial of the waste heat could be

recaptured than we stand a good chance to lower down the overall energy use. Currently, MicroPower is

developing the "world's most efficient

semiconductor chip" that can direct convert heat-to-energy with triple the conversion efficiency

than current market available technologies.

MicroPower’s device combines the best aspects of thermoelectrics and thermionics. It is said to

not only operate at significantly lower temperature ranges, but to also

hit an absolute efficiency rate of 18% at temperatures between 200˚C and

600˚C, comparing to current thermoelectric products deliver an efficiency rate

of 5%.

Although the energy savings using

MicroPower technology might only reach 10%, the overall impact on

the world could be significant, as Max Lewinsohn, the company's CEO,

related to Renewable Energy Magazine:

"If every heat engine in the world – every power plant, industrial plant, car, plane, etc. – could be made 10% more energy efficient, it would save an enormous amount of money and fuel – the latter being crucial as it would enable us to make better use of the limited resources we currently have at our disposal. This could play a crucial role in giving alternative forms of energy – solar, wind, geothermal, etc. – more time to develop and become commercially viable by the time we really do start running out of fossil fuels."

So, MicroPower could be the real game-changer in today energy crisis situation.

Tuesday, July 16, 2013

Dye-Sensitized Solar Cells Achieve 15% Of Efficiency

EPFL, Switzerland, has achieved a new record of 15% efficiency for dye-sensitized solar cells (DSSCs). DSSCs have many advantages over their

silicon-based counterparts. They offer transparency, low cost, and high

power conversion efficiencies under cloudy and artificial light

conditions. However, until now their overall efficiency has been lower

than silicon-based solar cells, mostly because of the inherent voltage

loss during manufacturing. Now, EPFL scientists have developed a new version of DSSC that is fabricated by a new two-step process raising their

efficiency up to a record 15% without sacrificing stability.

The

new DSSC uses a perovskite material as a

light harvester and an organic hole transport material to replace the

cell's electrolyte. Perovskite is a calcium titanium oxide mineral species. Typical fabrication of this new DSSC involves

depositing a perovskite material directly onto a metal-oxide film. The

problem is that adding the entire material together often causes wide

variation in the morphology and the efficiency of the resulting solar

cell, which makes it difficult to use them in everyday applications.

Michael

Grätzel's team at EPFL has now solved the problem with a two-step

approach: First, one part of the perovskite is deposited in to the pores

of the metal-oxide scaffold. Second, the deposited part is exposed to a

solution that contains the other component of the perovskite. When the

two parts come into contact, they react instantaneously and convert into

the complete light-sensitive pigment, permitting much better control

over the morphology of the solar cell.

The new method raises DSSC

power-conversion efficiency up to a record 15%, exceeding the power

conversion efficiencies of conventional, amorphous silicon-based solar

cells. The team believes that it will open a new era of DSSC

development, featuring stability and efficiencies that equal or even

surpass today's best thin-film photovoltaic devices.

Source: http://actu.epfl.ch/news/dye-sensitized-solar-cells-rival-conventional-ce-2/

Source: http://actu.epfl.ch/news/dye-sensitized-solar-cells-rival-conventional-ce-2/

Monday, July 15, 2013

A New Solar Thin-Film Process Could Cut Cost By 40%

Cadmium telluride (CdTe) has become the second most popular solar technology after silicon. It is the only thin-film technology to surpass crystalline silicon in cheapness for a significant portion of the PV market. One drawback of CdTe is small module size, stems from the use of high temperature CdTe deposition process.

REEL Solar Inc. (RSI), San Jose, U.S.A., announced that it has produced a 1.5 square meters CdTe module, doubled than the current CdTe module measured only 0.75 square meters. RSI's developed a new process called Rapid Efficient

Electroplating on Large-areas that both speeds the plating step and eliminates constraints on panel

area. RSI projects a manufacturing cost of less than US$0.40

per watt in 2014, which is 1/3 cheaper than current mass-produced thin-film and silicon based modules. This would be 3 years ahead of what First Solar, the world major CdTe solar manufacturer, has predicted.

Tuesday, July 9, 2013

New Phosphors could make LEDs To Shine More Like Natural Sun

LEDs are more efficient and have longer lifespan than incandescent and fluorescent lights. But technically it is still a challenge to make LED to produces warm, white light like sunlight. It turns out that creating phosphors that can emit a broad spectrum of wavelengths mimicking

natural light is a tricky business.

Natural light composes spectrum from ultraviolet to infrared (250 nm to 1800 nm of wavelength). When ultraviolet photons generated from LED hit a phosphor, white light will be emitted. The problem is that the spectrum of this LED's white light isn't broad enough to mimic sunlight, as shown below.

Scientists from Oak Ridge and Argonne national labs and the University

of Georgia, U.S.A., are working together to develop a new group of phosphors that

glow in a broader part of the spectrum.

“It’s hard to get one phosphor that makes the broad range of colors needed to replicate the sun," said John Budai,

an Oak Ridge materials scientist. “One approach to generating

warm-white light is to hit a mixture of phosphors with ultraviolet

radiation from an LED to stimulate many colors needed for white light."

They are growing and testing nanocrystals composed of europium oxide

and aluminum oxide powders. Europium is a rare-earth element that has

exceptional phosphorescent qualities, which glow in lots of different colors — some are

orange, purple, green or yellow.

They are using X-rays to understand how atoms are arranged in the

phosphorescent materials. Once they figure

out how altering crystal growing conditions change the colors emitted,

they hope to create lighting close to natural sunlight.

Monday, July 8, 2013

Flexible Glass Could Make Solar Power Cheaper

U.S.A. National Renewable Energy Laboratory have built flexible solar cells using a thin and pliable kind of glass, called Willow glass, from Corning, the maker of iPhone screen's cover glass. The new solar cells could potentially make rooftop solar power far cheaper.

Conventional solar panels are heavy, bulky, and breakable,

which makes them expensive to transport and install. Installation cost has been one of the largest parts of the overall cost

of

rooftop solar system. An average rooftop solar system in California

costs US$6.14 per watt, while some solar panels sell for less than US$1 a

watt in many cases.

Willow glass solar

shingles are lightweight and could be nailed to a roof in place of conventional shingles. It would simplify the installation and reduce overall cost. Also, unlike other solar shingles making from plastic, Willow glass is very good at sealing

out the solar elements from air and moisture, which helps solar cells last for decades.

Willow glass also makes

it possible to use cadmium telluride as the solar cell material. This is

the only material that’s been able to successfully challenge

conventional silicon solar cells at a large, commercial scale.

Cadmium telluride solar cells need to be made on a transparent

material. Other flexible, transparent materials either can’t handle the

high temperatures needed to make the solar cells, or they block too much

light, reducing efficiency.

Willow glass solar cell is still in the proof-of-concept status. There are still a way from commercialization. In addition to improving

efficiency, it will be necessary to develop a manufacturing process and equipments to handle larger

flexible solar cells.

Friday, July 5, 2013

99% Of Android Devices Are In Threat Due To Android's App Vulnerability

Finally, Android platform is no longer immune from hacking. Bluebox Security has

found a vulnerability in Android platform which could allow hackers to turn

virtually any Android app into a malicious “zombie”. This would allow hackers to silently and remotely control a device's function, without raising

the attention of the phone owner, Google or the app developer. This vulnerability dates back to Android 1.6 and could affect any of the 900 million Android devices in the market.

BlueBox Security's CTO Jeff Forristal revealed the company found a method by which a

hacker could modify an app’s APK code without breaking the cryptographic

signature used to authenticate it. Since verified apps are granted complete access to the Android system

and all applications on a phone, the security weakness is potentially

huge.

Forristal also mentioned that Apps listed on the Google Play store are immune from this tampering. This is yet another reason to stick to official apps stores for

downloads.

A report from Juniper

released last month claimed that mobile malware is an increasingly

profit-driven business. The research firm

estimates that the number of malicious mobile malware jumped 614%

between March 2012 and March 2013 to account for more than 250,000 apps.

Thursday, July 4, 2013

E. Coli Bacteria Has Been Experimented To Produce Biofuel

E. coli bacteria has been notorious for causing severe food poisoning. In bio-engineering field E. coli also famous of its ability to

produce the long chains of carbon and hydrogen atoms found in petroleum,

called fatty acids.

A research team from Harvard University's Wyss Institute, U.S.A, is

on track to transform E. coli into a producer of biofuels, pharmaceuticals, plastics and

just about anything else that is presently made from petroleum

precursors.

According to Wyss Institute, the tough part in the research is to get E. coli

to produce fatty acids that are just the right length. Long chains

containing more than 12 carbons are energy-dense but too gooey. Chains

that are too short don’t store enough energy and vaporize too easily. Hence, the aim is to produce chains between 4 and 12 carbons long.

An 8-carbon chain called octanoate, or caprylic acid, has been produced by altering the

metabolic pathway of E. coli that converts carbon from sugar into fatty acids. Try to imagine the pathway as a river, you can

visualize the chain growing longer as it flows downstream. By

genetically engineering the pathway to form “dams” or tighten up, you

shorten the process and therefore, shorten the length of the chain.

Caprylic acid only gets you part of the way to biofuel, though. The team is now working on a

process to convert octanoate to alcohols, which is just

one chemical step away from octane.